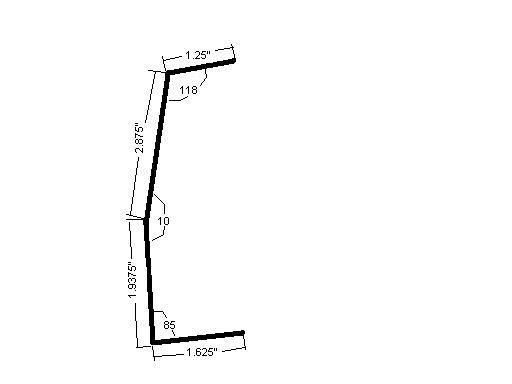

The top image is a measured drawing of what you will need to have made for you out of 3/16" stock. Click on the image to get a full view. I had mine made well before I cut into the rocker panel. What I found inside was a bit different than the drawing you see to the left.

My car had the original rockers in place so I had a chance to see the original support beam. It had the same basic shape as what is in the drawing, but it was turned so that the opening of the "C" was toward the car, not the outer panel. The second image shows how this "new" panel fits, but imagine the inner support flipped and you have what I found in my car.

You can see by these pictures, there is quite a bit of clean up work left to do, but you can see I ran a weld bead along the seam between the new panel and the car, then also put in a series of plug welds through then new rocker to weld the new rocker and the inner beam together.

To prevent rust, I coated the inside of everything with POR15. Now that it has been welded, I will need to hit it again since some of the rust coating will have burned off as the result of the heat.

This is possible because at the wheel wells, the rocker area is still open, just like a tube. This will allow me to get a coating inside before I seal it up. I think I will be wearing some POR15 for a while on my arms and hands as I do this with a swab. LOL.

I happened to have a piece of aluminum door sill from the tear down, and used it to check how the new rocker lined up. Sweet and straight dude!!