The windshield was completely removed for this replacement. Removal of the cowling is also required to avoid any additional damage to stuff you may want to keep.

You will see the lap joint there the old panel meets the dash and extends about 1 inch or so up onto the dash panel. As you remove this piece, you will notice it ends on the left and right before it gets to the fender. This gap was filled with lead in the original setup so don't get worried.

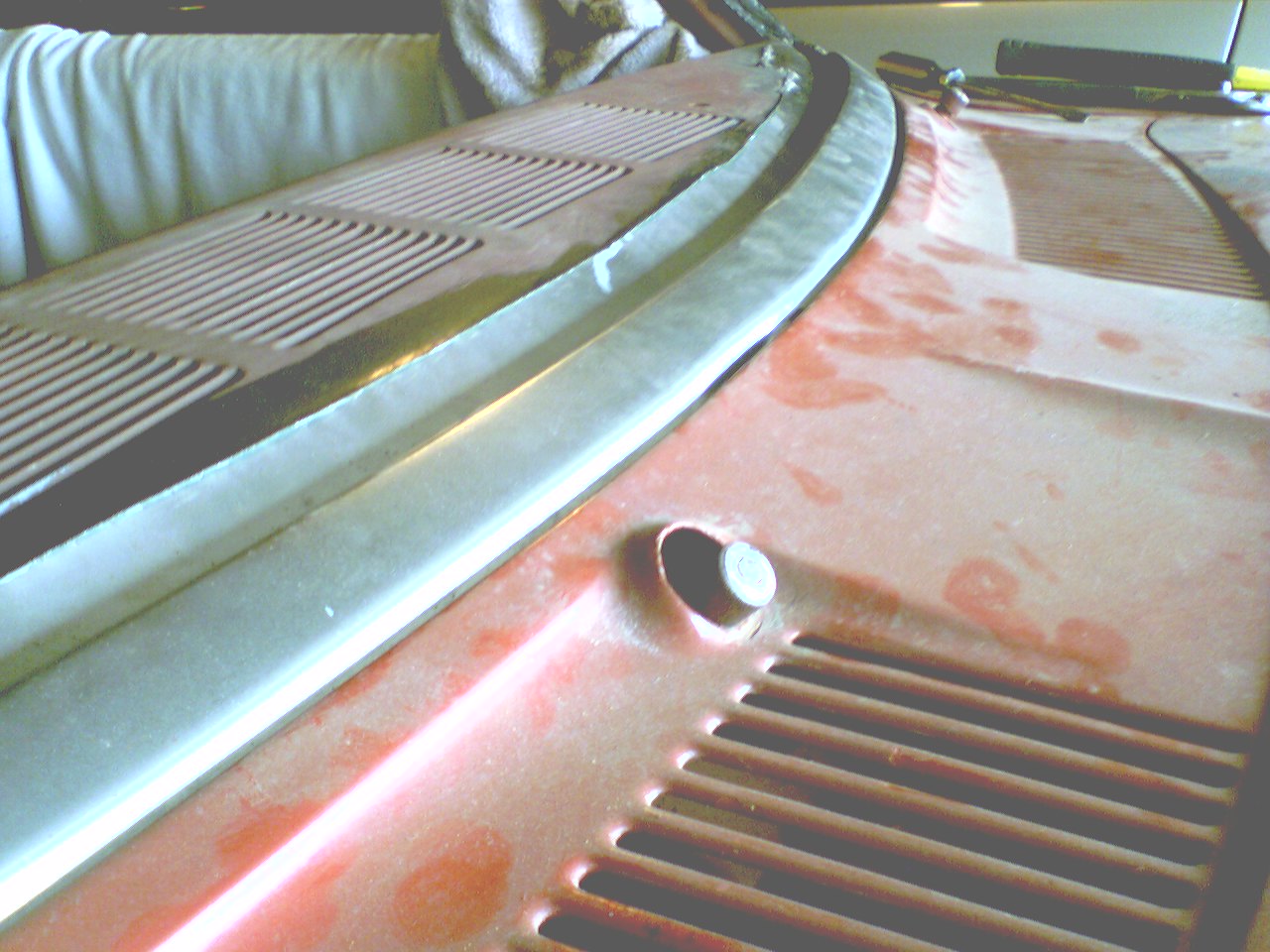

Removal of this piece must be done carefully to avoid damage the the grill on the dash panel. What you see in the top left picture is the area just after coating it with POR15. Note in the dead center of this picture there is a hole in the dash panel. The rust had extended this far. Fortunately the Clarks repair panel gives you quite a bit of extra steel to help account for this.

The middle left picture shows how I test fit my replacement panel to ensure I left enough to fill in the bad stuff on the dash.

The bottom picture shows a bit more of the "before" shot. Notice the repair panel put in place just to check fit. Also you will notice the rust around the remaining frame of the windshield as well. Some sharp eyes will also notice the steel bar running from the top of the windshield to the back of the car. I used these to ensure the distances etc. were the same on both sides of the car.

With the car on jack stands, it was clear there was some flex in the

body as the distances on the right and left of the windshield were

off. These braces fixed that problem before it was ugly. Door

gaps etc were rechecked to ensure everything was OK.

I did have some challenges with how the new piece fit. It didn't have the same bow in it as the what was in the original so I welded the left side as you see it, then went to the right and clamped down the edge into position and welded.

This caused some other fit problems with regard to the cowling. With the clamping of the ends into position, the sill piece flared up a bit where it meets the cowling, leaving an uneven gap from left to right.

Additionally I noticed the stud for the right windshield wiper was bottoming out on the cowling. From chats with folks who have done this, the fit issues are not unusual, and solutions include finding a cowling that does fit, or moving the stud. I am opting for moving the stud.

The second picture on the left shows this gap issue, and the stud position issue. Clicking on the image will give you a larger view of the gap I am talking about.