Ford Super Duty 4x4

Dana 60 Front Differential Gear Oil Change

2004 F250 4x4 XLT Sport Crew Cab

Click Here for a PDF version of this article

It was time to change the front diff gear oil so I decided to take a few pics of the process.

TOOLS & PARTS I USED

- 5/16 allen wrench

- Torque wrench

- Thin gasket scraper

- 4" angle grinder & wire wheel

- Drain pan

- Several rags

- Loctite silicone gasket maker, part number RTV 598

- Green Scotchbrite pad

- Redline #75W90NS gear oil, 3 quarts

- An old, empty gear oil bottle

- Lacquer thinner

- Rattlecan primer & paint

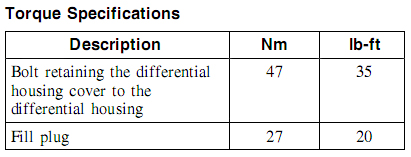

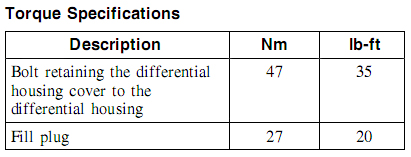

Here's the torque specs for the involved fasteners in this project

Here's the oil & gasket maker I used.

Before getting started, I broke the fill hole plug loose with a 3/8 drive ratchet. Its just easier to break it free when its still on the truck.

Remove the front differential cover by removing the bolts. Nine of them are 9/16" hex head bolts and one is a socket head cap screw (with a washer) that requires a 5/16" allen wrench. I left the two top bolts in place to hold the cover while the bulk of the oil drained out.

Use the scraper tool to break the seal and let the oil drain.

Once most of the oil has drained, remove the last two bolts, remove the cover, and allow the case to drain.

I used the time it took the diff to finish draining to do a little work on the cover.

I cleaned the gasket surface with the scraper tool, then cleaned the area with a scotchbrite pad, and then did the final cleanup with some rags and lacquer thinner.

Its pretty typical for the cover to have rust on it which could eventually lead to problems. I spent a few minutes with the 4" angle grinder cleaning up the worst of it. Then hit it with some primer and paint.

Now, back to the axle housing. Use a few rags to wipe the excess oil, out of the bottom, that didn't drain.

Inspect the gears to make sure there are no chipped teeth, cracks, or weird looking wear patterns.

Next, place a rag around the gears to keep the gunk out of them while cleaning up the gasket surface.

I cleaned up the gasket surface using the same steps I did on the cover -- scraper, scotchbrite pad, rags, lacquer thinner.

Now that the axle housing and cover are both clean and ready for reassembly, the next step is to apply the RTV gasket sealer. I put about 1/4" bead around the perimeter, circling the holes. Let the RTV skin over for about 20 minutes.

Next, install the cover and torque the bolts to 35 ft lbs.

Wait at least an hour before re-filling the front diff.

I used Red Line 75W90NS, which does not have friction modifier in it. I used an old empty gear oil bottle to fill the diff.

I poured the Red Line into it and then used the old bottle to squeeze it in to the diff. It will take almost three quarts and you're done when it starts to seep out of the fill hole.

Reinstall the fill hole plug and you're done!

Questions or Comments? Email jmray@frontiernet.net